Thermoacoustic Stirling Cryocooler How It Works

RIX manufactures highly reliable, thermoacoustic Stirling (pulse tube) cryocoolers for a variety of OEM, Military, and R&D applications.

In this guide:

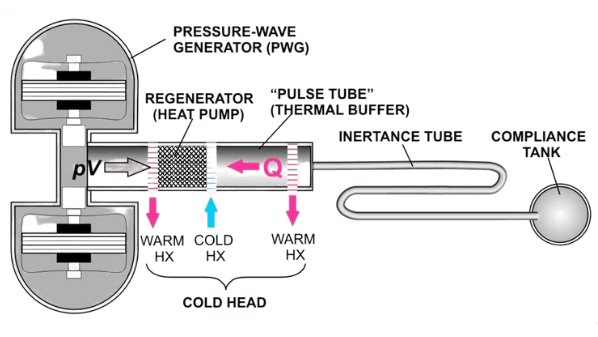

The Process

- Pressurized helium gas is cyclically compressed and expanded relative to the mean pressure (charge pressure) by the pistons of the PWG.

- With each forward stroke of the pistons, the gas moves through the aftercooler, or warm heat exchanger, where heat is removed. The gas parcel continues through the regenerator, which precools it before reaching the cold heat exchanger..

- As the gas moves toward the cold heat exchanger, gas in the thermoacoustic network (thermal buffer tube (sometimes called a pulse tube), hot heat exchanger, reservoir) also moves in the same direction. Even as the driven gas stops advancing, when the pistons reach their upper limits, the network’s gas continues moving, driven by its own inertia in the high-speed inertance tube. This acts like a virtual piston, moving away from the cold exchanger, which expands the gas in that area. As it expands, it gathers heat from surroundings (the area or substance to be cooled).

- The pistons begin withdrawing and helium then moves back through the regenerator and aftercooler. Still delayed by its inertia, the gas in the network follows and the cycle begins again.

The heat exchangers are cooled by local water, or an optional closed water loop that consists of a reservoir, a pump, and a liquid-to-air heat exchanger. If an air-cooled cryocooler is desired, the motors and warm heat exchangers are cooled by a fan which blows over the motor enclosures and a heat sink connected to the aftercooler. This option is only available on RIX’s smaller cryocoolers, the 2s102K and 2s132K. It is recommended that these small PWG’s be convectively cooled during operation to assure optimal performance from the cryocooler.