Reliable Performance for Onboard Systems

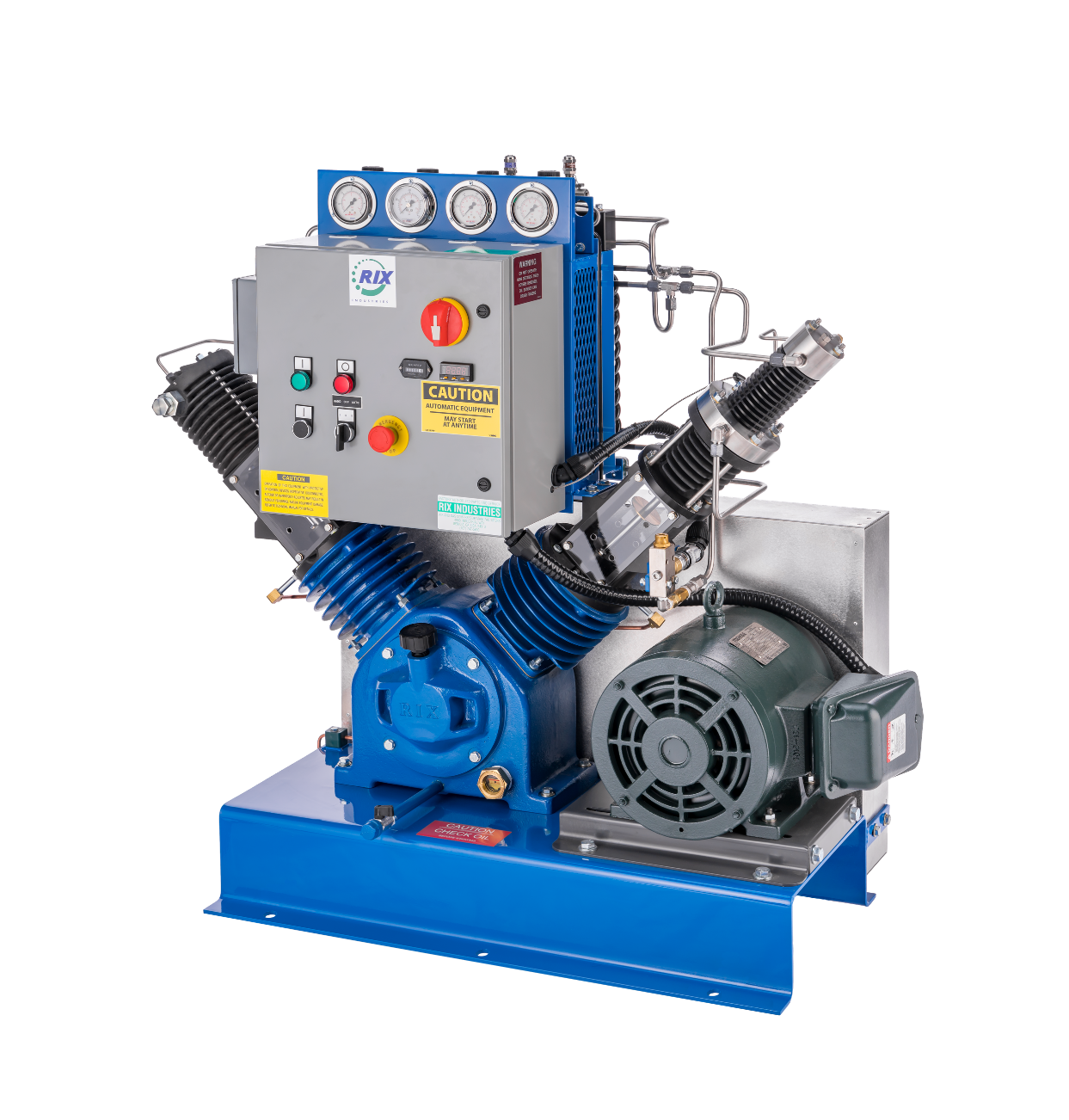

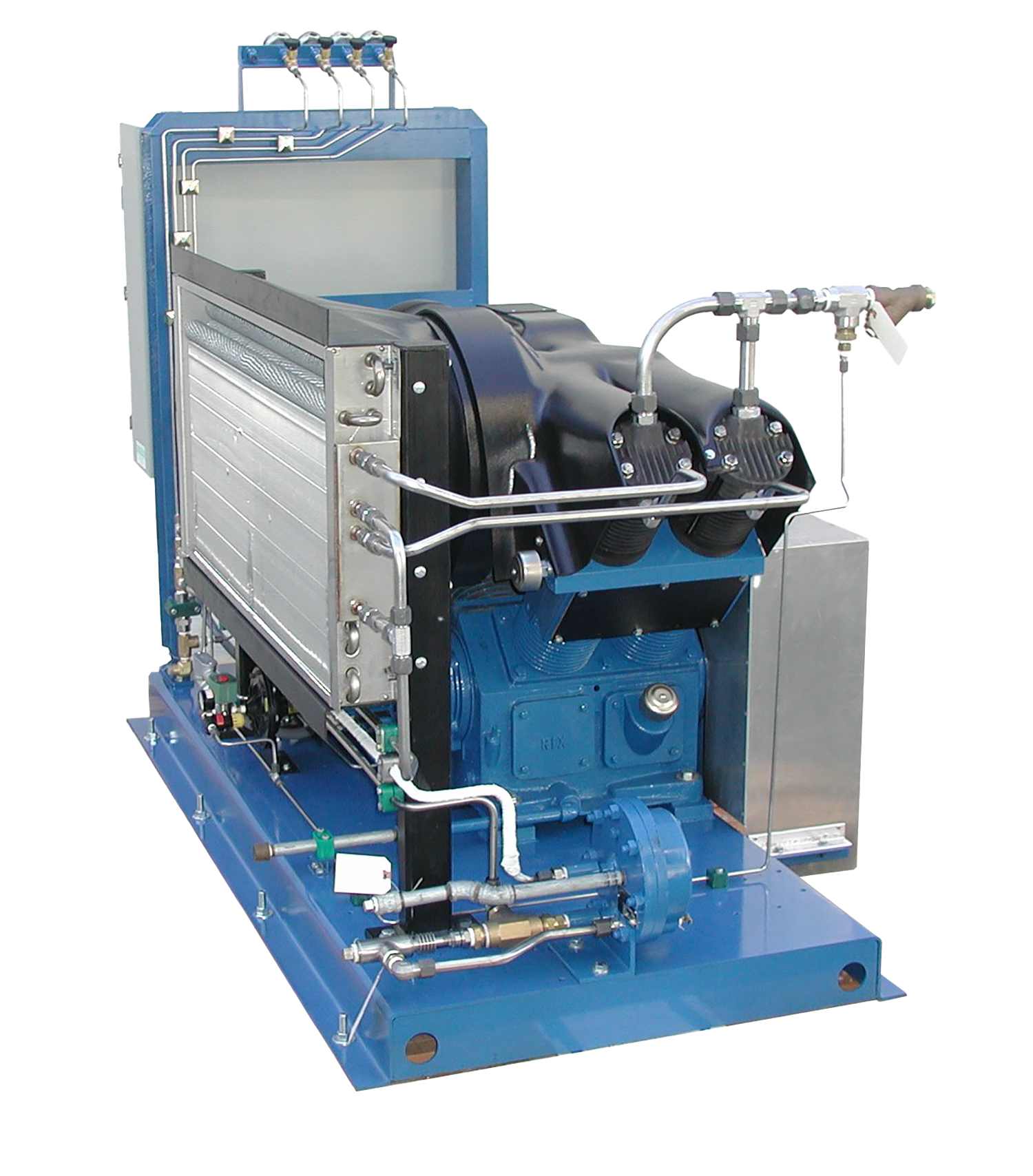

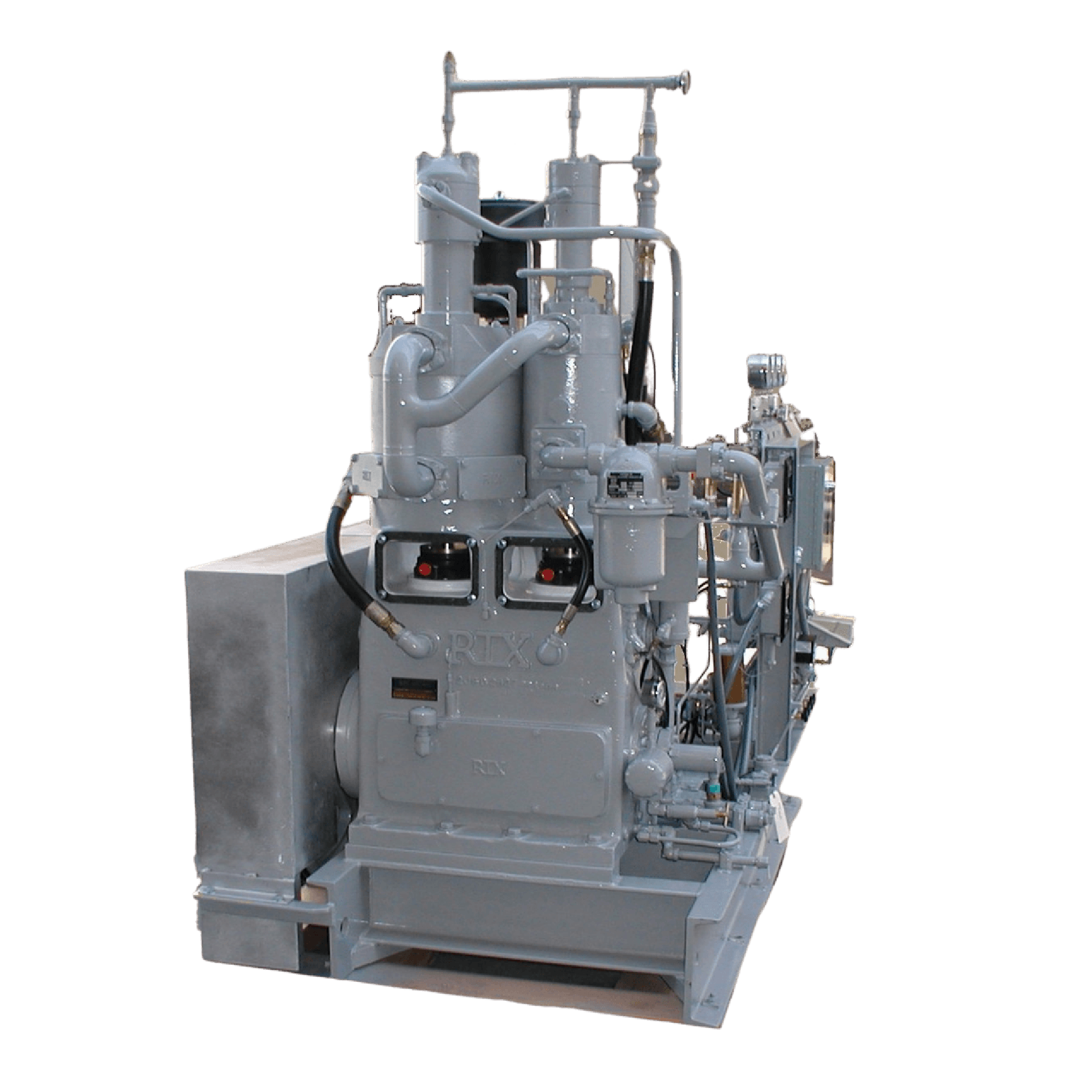

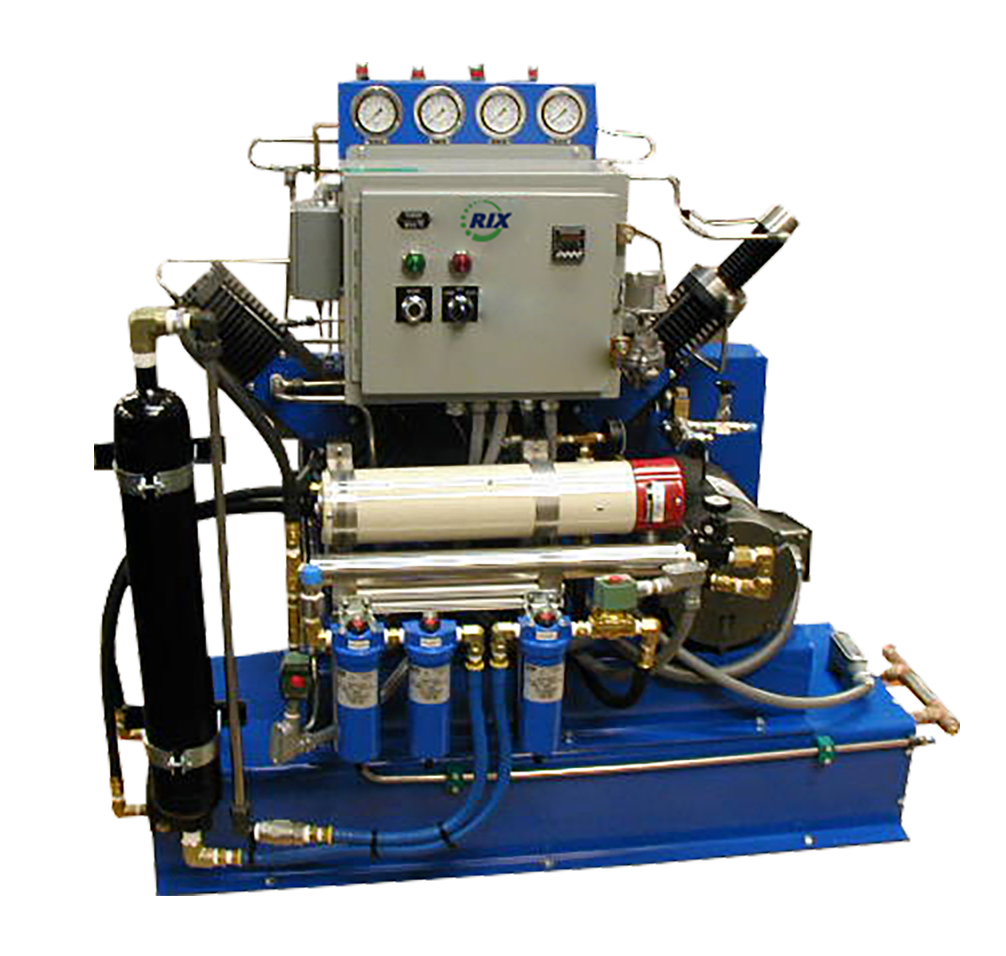

At RIX Industries, we've been at the forefront of high-performance compression technologies since 1878. Today, our commercial marine compressors deliver precision-engineered reliability for demanding marine applications—designed to operate in extreme marine environments, from offshore supply vessels to tankers, ferries, cruise ships, and commercial shipping fleets.

Whether you're starting massive diesel engines, supplying high-pressure breathing air, or powering deck equipment, our compressors ensure mission readiness, 24/7 operational uptime, and full compliance with maritime regulations. RIX compressors, from shipboard systems to portside infrastructure, are trusted for their durability, flexibility, and performance.

Offshore Operations

- Improve air quality and temperature in enclosed spaces.

- Ensure efficient ventillation.

- Regulate conditions for senstive equipment.

- Enhance crew comfort.

Refrigeration and Climate Control

- Supply compressed air in cooling cycles to preserve cargo, improve energy efficiency, load management, and regulate crew comfort.

Renewable Energy

- RIX partners in the research and development of systems and technologies that support advancements in sustainable solutions.

Purpose Built for the Marine Environment

RIX oil-free compressors reduce contamination risk, simplify maintenance, and maximizing uptime in critical operations. Our compressors are tested and proven to withstand salt spray, humidity, vibration, and fluctuating power sources. Designed for full compliance with marine classifications (including DNV and ABS), RIX compressors are built with:

- Oil-free compressed gas

- Corrosion-resistant housings and components

- Closed-loop cooling options

- Explosion-proof configurations for hazardous locations

- Shock and vibration mitigation options

Marine operations require systems that perform flawlessly under pressure—literally.

Our Reliable Compressors are Tailored for a Wide Range of Marine Industry Applications

Spare Parts & Lifecycle Support

Maritime downtime is not an option. RIX provides a full range of spare parts for marine applications, with global support and shelf-ready inventory. Our service model ensures fast access to:

- OEM-CERTIFIED REPLACEMENT PARTS

- MAINTENANCE KITS & CONSUMABLES

- REMOTE TECHNICAL ASSISTANCE & FIELD SERVICE SUPPORT

Our compressors are engineered for long life cycles, and detailed technical specifications and documentation are provided upfront to streamline integration, commissioning, and ongoing maintenance.